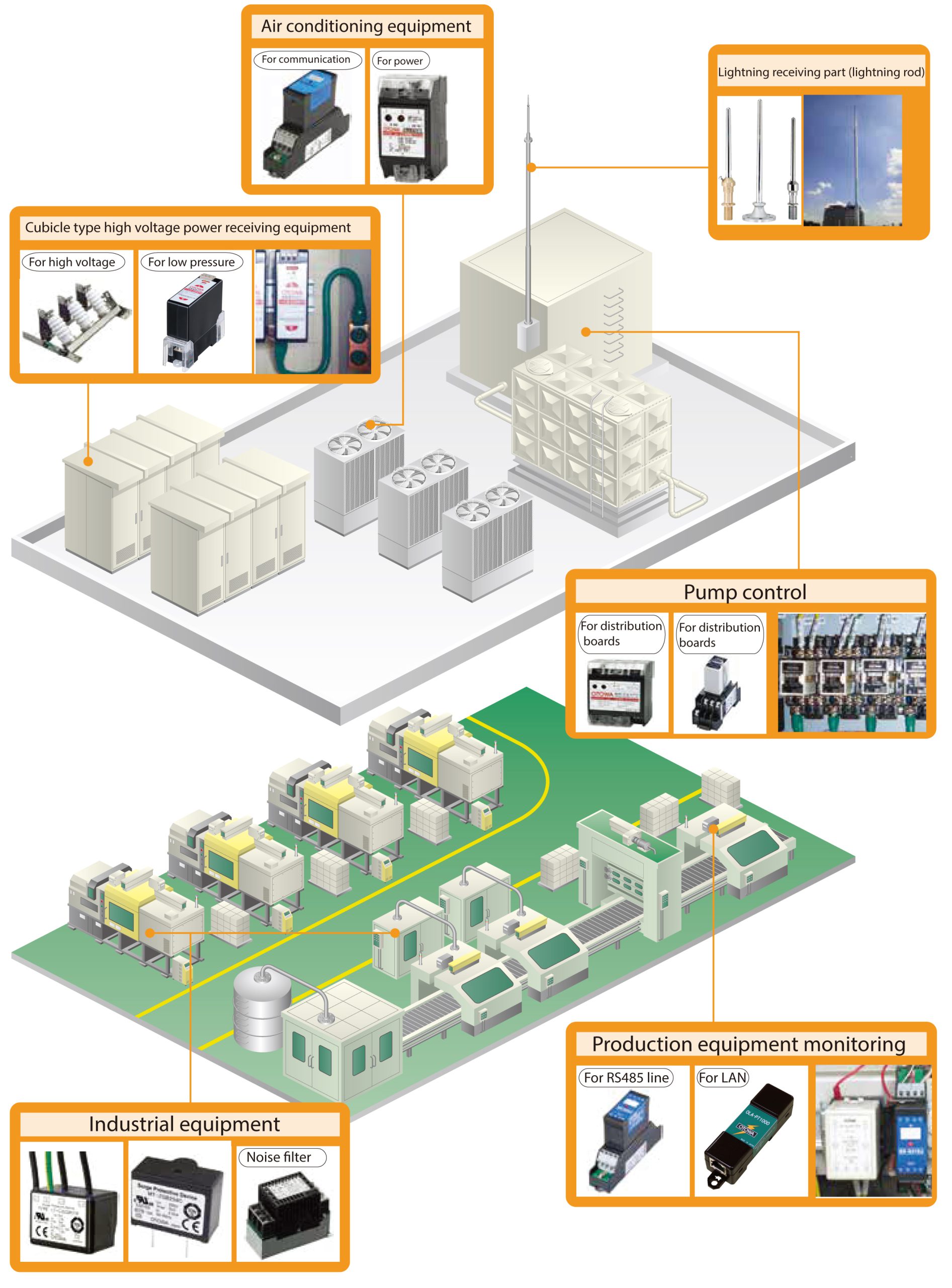

Modern factories are built with all equipment controlled and extensively networked. The factory is wired in a variety of ways. For example, remote monitoring is done between the factory and the head office using serial communication such as RS485 to monitor production equipment. Even within the factory premises, wiring for pump control, communication, ITV cameras, etc. are connected between the factory and different buildings. When there are production facilities in multiple buildings, there are various types of wiring running between the buildings. In many cases, the wiring is several dozen meters to several hundred meters long, making it easy for a potential difference to occur between the grounds (making it easy to be affected by lightning surges).

In addition, factories are often located in the suburbs near mountainous areas, and because mountainous areas are prone to updrafts, thunderclouds are easily generated, making them even more susceptible to the effects of lightning.