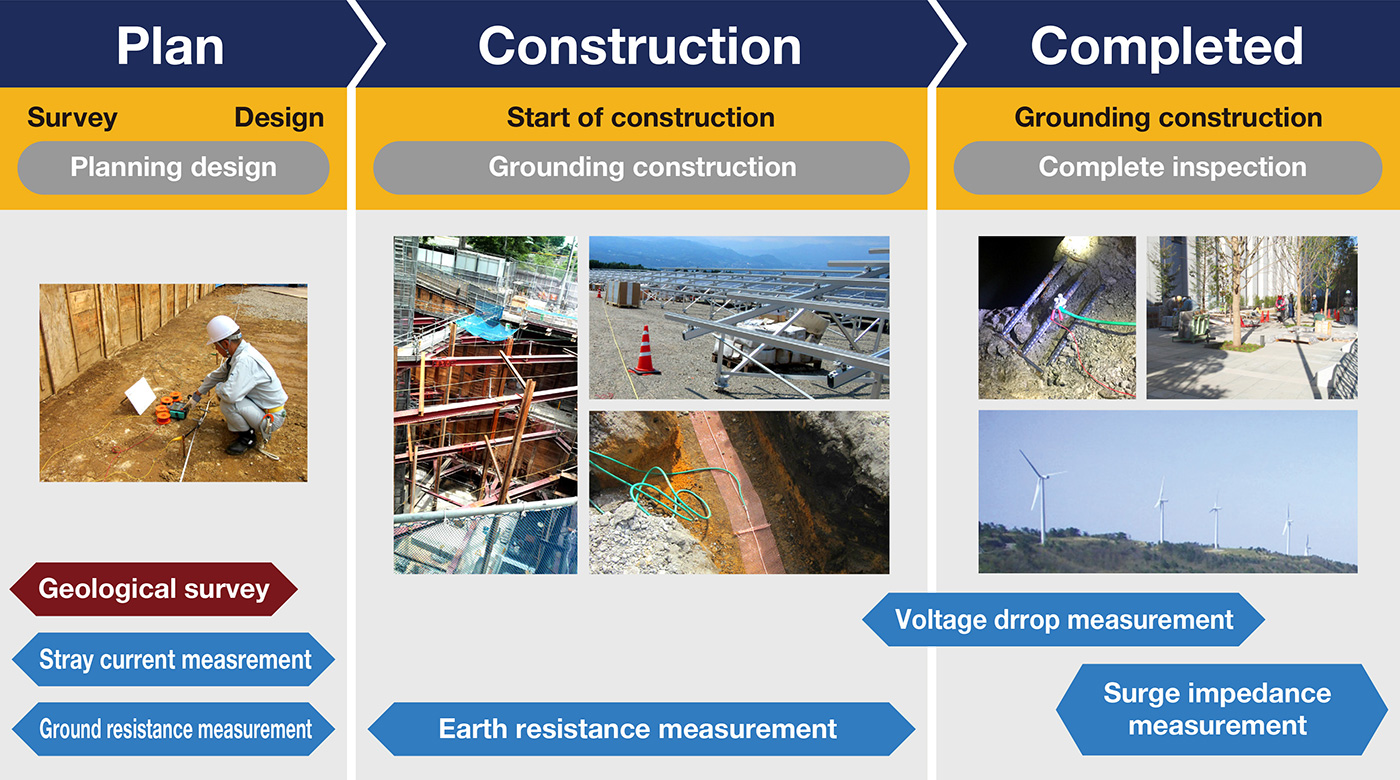

The purpose of grounding electrical equipment is to ensure safety to protect people and equipment from electric shock and leakage accidents (safety grounding) and to ensure system functions to operate electrical equipment in a good environment (functional grounding).

The electrical and electronic equipment used in factories and offices, as well as the equipment in renewable energy facilities, is very delicate due to the use of electronic technology. Grounding is an important system that is indispensable for operating these electrical facilities in a safe and favorable environment. It is also important to know the exact ground resistivity of the site for proper grounding design.

Our grounding consulting service will help you solve these questions and build a safe and inexpensive business environment.

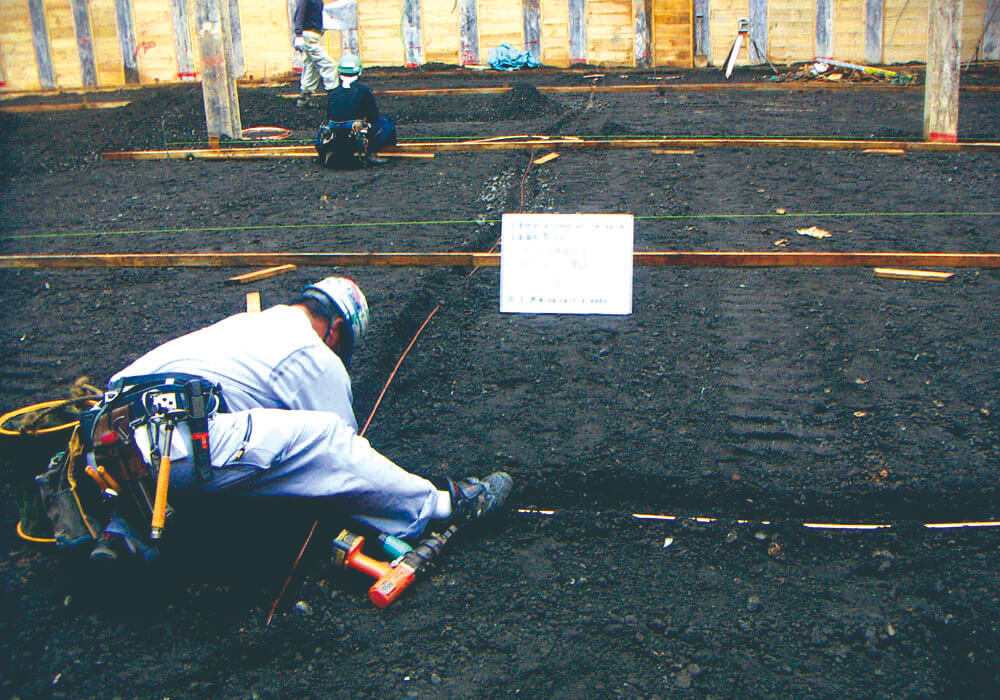

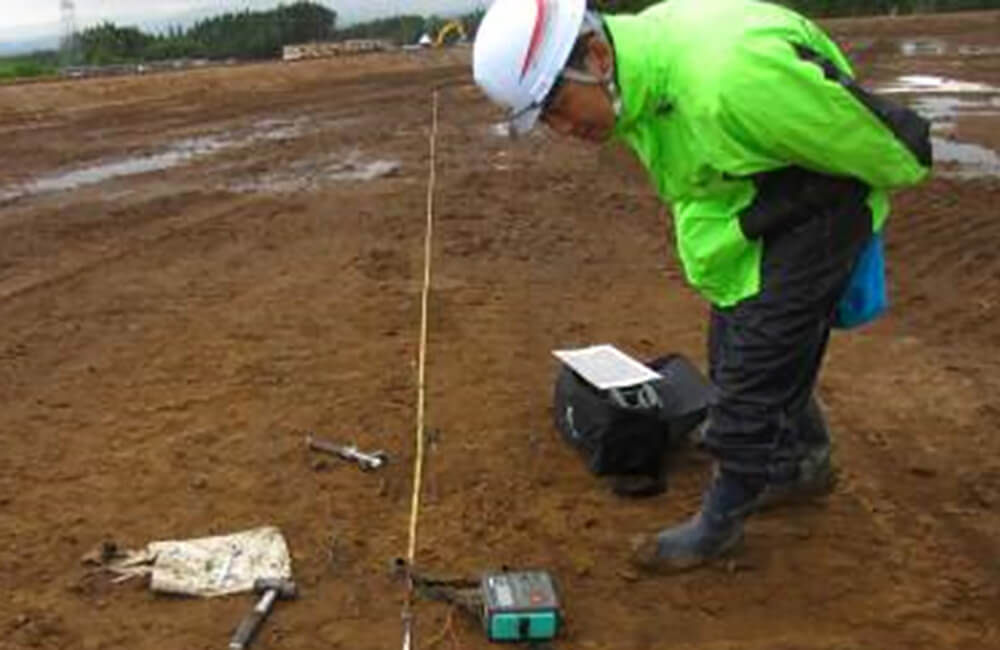

We measure the earth resistivity of the soil on site and use it as an indicator for grounding design.

Click here for details

Measurement of the ground resistance of large-scale grounded objects, such as structure grounding, requires measurement of the ground resistance using the voltage drop method.

Click here for details

In the vicinity of electric railroads that use direct current, electric corrosion may occur in the equipment, and measurement of stray current is necessary when installing storage tanks for hazardous materials under certain conditions.

Click here for details

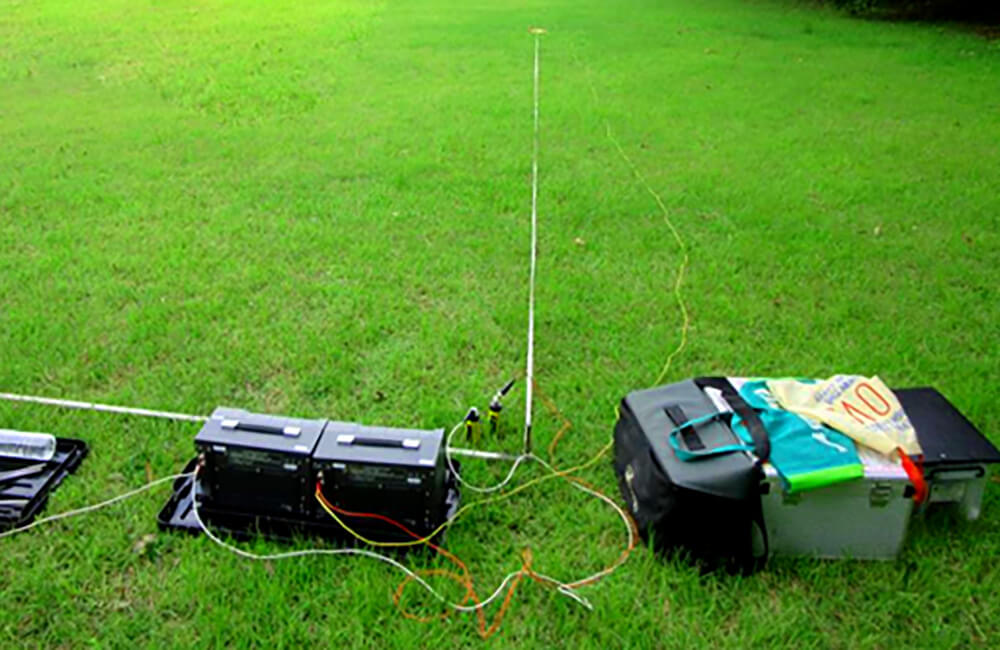

Measure the transient grounding resistance (effective surge impedance) that cannot be measured with a grounding resistance meter.

Click here for details

STEP01

What kind of problem do you need help with? Please provide specific information such as purpose, facility and location.

In order to operate and use electrical equipment safely, it is essential to satisfy the grounding performance and standard requirements indicated in the technical standards for electrical equipment.

Please feel free to contact us first. We will be happy to advise you on the appropriate policy. There is no charge up to this point.

STEP02

Based on the construction plan documents and drawings provided by the customer, we will examine the most appropriate measurement (method, location, point, etc.) for the customer's protection purpose and prepare a measurement manual.

After confirming the problems (equipment environment, weather environment, etc.) in advance of measurement, we will conduct on-site investigation and measurement.

STEP03

After confirming the situation at the site, we carry out necessary measurements such as earth resistivity measurement, stray current measurement, and surge impedance measurement at the site based on the procedure manual.

STEP04

We analyze and evaluate the measurement results, and propose the optimal grounding that best suits the environment and purpose.

At the customer's request, we propose a grounding design and construction method with a high investment effect according to the site conditions.

STEP05

While complying with standards and specifications and giving priority to safety measures, we proceed with construction using a rational method that gives due consideration to safety and economy in accordance with the conditions of the construction site.

Even in the case of direct construction by the customer, we will provide on-site construction guidance upon request.