Lightning, a natural threat, is unpredictable. It is said that the lightning current from a single lightning strike is about 30-40kA, but in rare cases, lightning current of 200kA or more can occur.

In addition, guerrilla thunderstorms have been on the increase in recent years, so it can be said that the risk of lightning damage is increasing. In order to maintain the performance of SPD and surge arresters, we propose inspections and regular maintenance before and after lightning strikes.

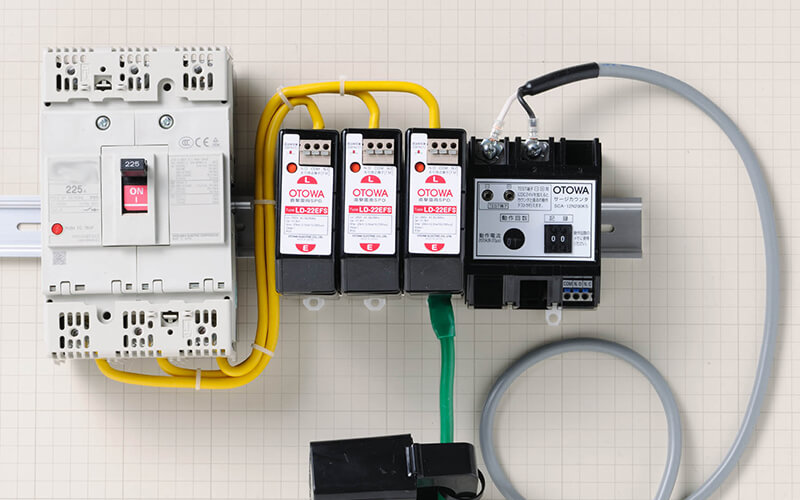

OTOWA’s SPDs and surge arresters sacrifice themselves to protect equipment when lightning surges greater than expected enter the equipment. At this time, the SPD and surge arrestor will be in a state of failure and will be safely disconnected from the circuit, but since the SPD and surge arrestor will not be installed, the equipment will not be protected if the lightning surge enters again.

We repeatedly test the performance of our products when we develop them.

Maintenance and inspection are essential for maintaining an optimal lightning protection system. No matter how good the lightning surge reduction measures are, if maintenance is neglected, the effects of the measures may not be fully demonstrated. Inspection and maintenance are recommended to keep the countermeasure in a state where it can fully demonstrate its effect. We perform preventive maintenance (time-based maintenance, condition-based maintenance) and post-maintenance (function stoppage type failure, function degradation type failure), and propose the most appropriate countermeasure for the customer’s facility.

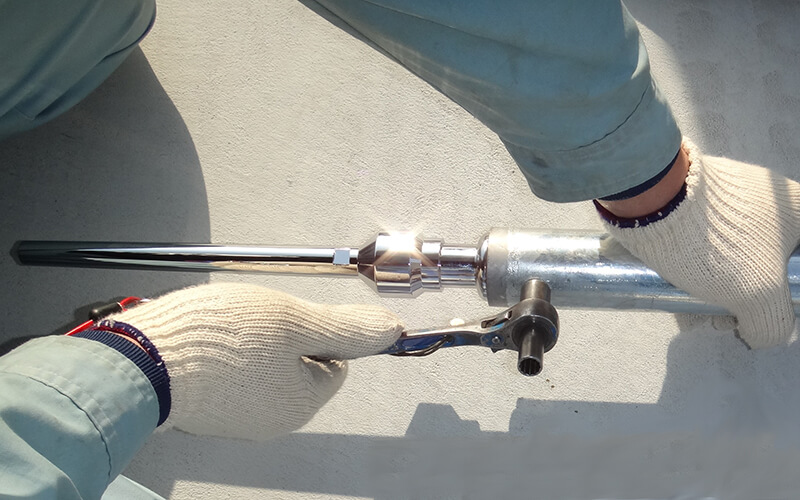

Measurement of SPD operation start voltage

Maintenance of lightning rod (lightning receiving section) (checking for loosening of the bottle).

With the increasing number of unmanned facilities, the demand for remote monitoring is increasing, and we have products that can remotely show the status of SPD (normal, needs replacement, deteriorated).

SPDs and surge arresters do not know whether they have treated lightning surges or not. By knowing how many times the SPD has handled lightning surges, it is possible to determine the life of the SPD and the effectiveness of lightning countermeasures.

Knowing the number of times the SPD has handled lightning surges can also be used as an indicator for maintenance.

In addition, by simply attaching this device to the wiring you are concerned about, you can check whether or not lightning surges are entering from that wire, not just the SPD’s ground wire. Knowing the path of lightning surge intrusion is the first step in lightning countermeasures. We also have rental products that can be used for easy countermeasures.

Many SPDs, including SPDs for power supplies and signal lines, use a plug-in system, so only the element part (element part) can be replaced.

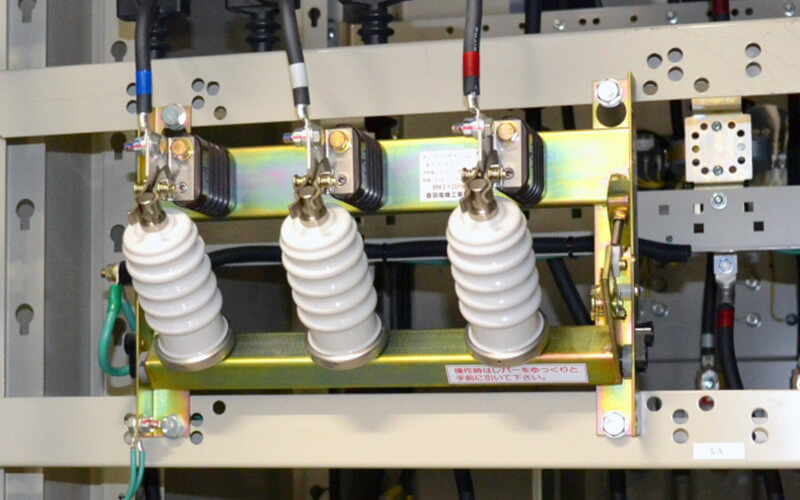

The Japan Electrical Manufacturers’ Association (JEMA) recommends that lightning arresters for power distribution and cubicles be renewed after 15 years of use.

This recommended renewal period indicates the time when it is generally considered more effective, including economic efficiency, to replace them with new ones due to the aging of the components of each device, etc., when they are used under normal conditions with normal maintenance and inspection.

The mechanical structure of outdoor lightning arresters is simple enough to withstand harsh environments, and visualization of deterioration is limited because deterioration is determined visually using deterioration indicators. Lightning arresters for power distribution and cubicles also deteriorate in the face of repeated or excessive lightning surges. It is precisely because visual confirmation is difficult that we recommend a recommended renewal period of 15 years.

OTOWA has been providing maintenance services for solar power generation systems, which have spread rapidly in recent years, from the very beginning. Although solar power generation equipment is said to be maintenance-free, regular inspections are essential to ensure safe operation. We recommend regular inspections of solar power generation systems for stable power generation.